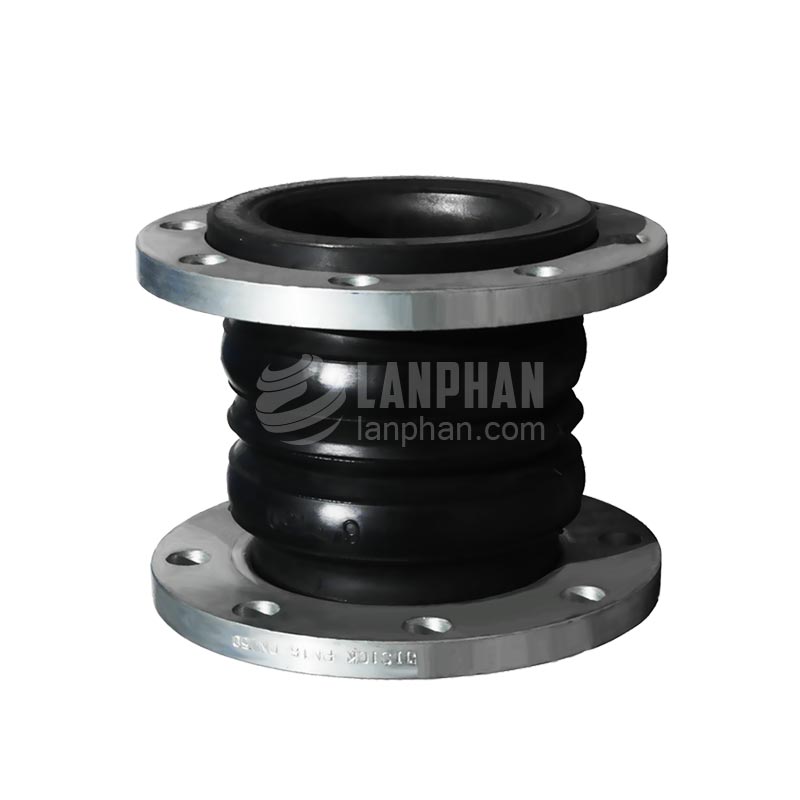

The GJQ (X) -SF-I type flexible rubber joint belongs to the double ball type, which is connected with a small edge of the clamping groove type flange. Due to the card slot connection way sealing performance is not as good as the end face full sealing connection, The maximum diameter of GJQ (X) -SF-I type rubber joint can only reach 400mm. And the smallest diameter is 32mm. Compared with GJQ (X) -DF-I type rubber joint, the length for GJQ (X) -SF-I type joint is longer. The flexible rubber joint length for DN32 reaches 165mm, the length for DN400 also reaches 400mm. The same diameter of GJQ (X) -SF-I type rubber joint has larger axial displacement and radial displacement.

Let's use the GJQ DN32 (X) -DF-I type flexible rubber joint and GJQ (X) -SF-I flexible rubber joint as an example to compare. From the inner material and outer material, these two kinds of rubber joints has same material. Compared with GJQ (X) -DF-I type flexible rubber joint,The length of GJQ (X) -SF-I type has 75mm longer than it, also 24mm elongation larger, 40mm compression larger, radial displacement larger .But deflection displacement of the two are the same, which is 7.5 degrees. It is worth mentioning that the GJQ (X) -SF-I rubber joint of DN32 to DN150 has same radial displacement and deflection displacement, which is 45 and 7 mm. But the axial displacement becomes larger with the increase of the rubber joint length.

Product Alias:Flexible Rubber Joint,Rubber Joint,Rubber Soft Connection,Shock Absorber,Flange Soft Connection,Flexible Rubber Joint,Rubber Pipe Joint,Compensator,etc

Product Specifications: DN32mm - DN3600mm

Product Pressure: 0.6-2.5 MPa

Level of Shock Absorption: A level, shock absorption is very high

Product Certification: ISO9001:2008

Scope of Application: acid, alkali, corrosion, oil, hot and cold water, compressed air, compressed natural gas, etc

Product Color: black, physical color see goods display pictures

Working Temperature: 15-115 ℃ (ordinary) / - 30-250 ℃ (special)

|

DN Diameter |

FF Length (mm) |

Axis displacement |

Radial displacement |

Deflection displacement |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type-I | Type-II | Type-I | Type-II | Type-I | Type-II | |||||

| mm | inch | Extension | Compression | Extension | Compression | |||||

| 32 | 1¼″ | 165 | 30 | 50 | 45 | ±7.5° | ||||

| 40 | 1½″ | 165 | 30 | 50 | 45 | ±7.5° | ||||

| 50 | 2″ | 165 | 30 | 10 | 50 | ±7.5° | ||||

| 65 | 2½″ | 175 | 30 | 50 | 45 | ±7.5° | ||||

| 80 | 3″ | 175 | 30 | 50 | 45 | ±7.5° | ||||

| 100 | 4″ | 225 | 35 | 50 | 45 | ±7.5° | ||||

| 125 | 5″ | 225 | 35 | 50 | 45 | ±7.5° | ||||

| 150 | 6″ | 225 | 35 | 50 | 45 | ±7.5° | ||||

| 200 | 8″ | 325 | 35 | 60 | ||||||

| 250 | 10″ | 325 | 35 | 60 | ||||||

| 300 | 12″ | 325 | 35 | 60 | ||||||

| 350 | 14″ | 325 | 35 | 60 | ||||||

| 400 | 16″ | 400 | 65 | 70 | 70 | ±12° | ||||

| 450 | 18″ | 400 | 65 | 70 | 70 | ±12° | ||||

| 500 | 20″ | 400 | 65 | 70 | 70 | ±12° | ||||

| 600 | 24″ | 400 | 70 | 75 | 75 | ±12° | ||||

| 700 | 28″ | 450 | 70 | 75 | 75 | ±12° | ||||

| 800 | 32″ | 450 | 70 | 75 | 75 | ±12° | ||||

| 900 | 36″ | 450 | 70 | 75 | 75 | ±12° | ||||

| 1000 | 40″ | 500 | 75 | 80 | 70 | ±12° | ||||

| 1200 | 48″ | 500 | 75 | 80 | ±10° | |||||

| 1400 | 56″ | 500 | 75 | 80 | 70 | ±10° | ||||

| 1600 | 64″ | 500 | 75 | 80 | 70 | ±10° | ||||

| 1800 | 72″ | 550 | 80 | 85 | 65 | ±10° | ||||

| 2000 | 80″ | 550 | 80 | 85 | 65 | ±10° | ||||

| 2200 | 88″ | 550 | 80 | 85 | 65 | ±10° | ||||

| 2400 | 96″ | 550 | 80 | 85 | 65 | ±10° | ||||

| 2600 | 104″ | 550 | 80 | 85 | 65 | ±10° | ||||

| 2800 | 112″ | 550 | 80 | 85 | 65 | ±10° | ||||

| 3000 | 120″ | 550 | 80 | 85 | 65 | ±10° | ||||

Pre-Sales Service

- According to product’s using condition, technicians will offer rationalization;

- Provide detailed product performance specification;

- Provide professional quoted price;

- Provide 24-hour technical consulting reply.

In-Sales Service

- Begin to supervise from raw material, its qualified rate can reach to 100%;

- Whole manufacturing process are in strict accordance with promised procedure requirements, product qualified rate can reach to 100%;

- Provide product’s inspection record of key junctures to customers;

- Provide production schedule photos to customers at regular intervals;

- Package and transport products strictly accordance with export standard.

After-Sales Service

- Under the premise of correct installation, normal maintenance and using, we guarantee one-year warranty period;

- When warranty period has expired, our sold products enjoys lifetime guarantee repair, we only charge cost price for changing product’s standard component and sealing component;

- During installation and adjustment period, our after-sale service staff will communicate with customers frequently to know product’s running state in time. Assist customers to install and adjust products until customers are satisfied;

- If product has malfunction during operation period, we’ll offer you satisfied answer in time. We’ll reply you within 1 hour and provide solution or send staff to spot within 24 hours after receiving maintenance notification.

- Lifelong free technical support. Conduct satisfaction survey and inquiry equipment running condition to clients by telephone or e-mail semiannually from the first day of equipment running, put on records of acquired information.

1. Is the flange galvanized?

Yes, carbon steel flange not painting anticorrosive paint must be galvanized in order to avoid rusting. Usually, we choose electronic galvanized and hot dip galvanized, and most of our customers will choose hot galvanizing.

2. What kind of standard of your drilled flange?

Besides Chinese national standard, we also support American standard, German standard, British standard, Japanese standard, European standard and Australia standard. If you can give us the center distance of the hole, the number and diameter, we can also produce customized flange.

3. Does your company have spool type?

Yes, considering that the pipe length will be longer or shorter than the expection after finishing the installation of the pipes and the cost of producing new mold is expensive, we can produce spool type according to your requirements

4. Can the inner layer rubber and outside layer rubber be made using different rubber?

Yes, we can produce the rubber joint according to the environment the rubber joint is used in, and we will choose different rubber for the inner layer and outside layer.

5. Can I only buy ball without the flange?

Yes, and the price will be cheaper. For small diameter rubber joint, we have goods in stock and we can offer you a free hydrotest, but for large diameter rubber joint you need order.

6. How long is your product’s warranty?

12 month. From the day the customer receiving the goods, we grant a free replacement if the products have any problems during the guarantee period.

7. Can you offer the rubber joint sample?

For standard type of rubber joint we can offer the sample, but the customer will afford the freight. For non-standard rubber joint or more quantity, we will charge for the sample.

8. Does the rubber joint have inspection report?

Yes, all of our product will be conducted hydrotest and leave the factory with a qualified inspection report.

9. Can you offer the drawing?

Yes, we have a excellent engineer team, and they will offer your professional drawing and technical support.

1.28 years manufacturing experience.

2.The largest size in China:DN3600MM.

3.The longest service life, DN2600 single sphere rubber expansion joint for Tianjin Jiangbei Power Plant in 2008, it still works now.

4.Qualified Nuclear Power Plant supplier,DN2800 single sphere rubber joint for Jiangmen Nuclear Power Plant.

5.Competitive price, our price is not the lowest and not highest.